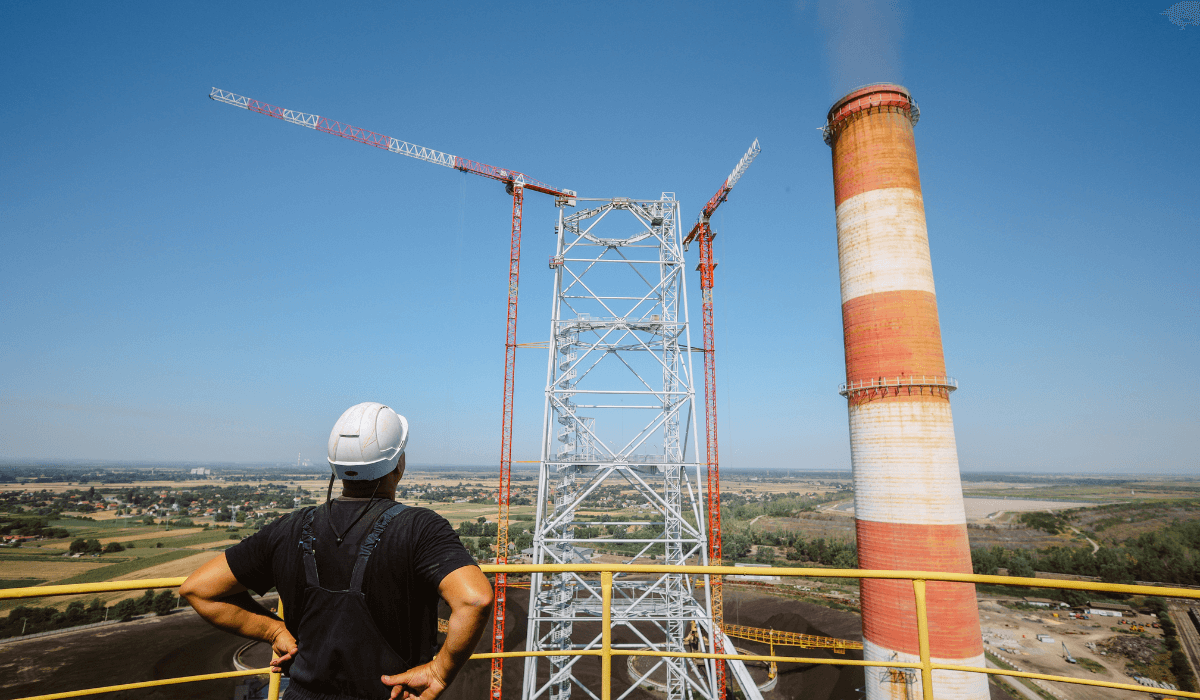

The safety and well-being of workers in coal-fired power plants is of utmost importance. It is crucial to ensure high levels of Health, Safety, and Environmental (HSE) awareness among Malaysian workers in these plants. The role of consultants becomes paramount in enhancing safety practices and implementing control measures to mitigate potential hazards.

Consultants play a critical role in promoting a safe and healthy work environment. They bring their expertise and experience to the table, helping organizations conduct thorough risk assessments and identify potential hazards. By partnering with consultants, power plants can implement control measures that ensure the welfare of their workers.

The ever-increasing service demands and the higher waste generation in major cities of Malaysia necessitate the involvement of consultants in the construction and operation of coal-fired power plants. Consultants possess the necessary knowledge and skills to develop and implement effective safety programs, formulate safety policies, and ensure compliance with relevant legislation.

The continuous improvement of HSE practices, as guided by consultants, leads to the long-term sustainability of waste-to-energy implementation. It enables power plants to produce electricity in an environmentally responsible manner while minimizing the potential risks associated with waste management.

In the following sections, we will explore the specific responsibilities of consultants in enhancing HSE awareness and delve into the strategies and best practices they employ. Additionally, we will address the challenges faced in enhancing HSE awareness among Malaysian workers in coal-fired power plants and discuss the future prospects of the industry.

Role of Consultants in Enhancing HSE Awareness

Expert HSE consultant plays a vital role in promoting a safe and healthy work environment among Malaysian workers in coal-fired power plants. Their expertise and experience enable them to effectively assess risks, identify hazards, and implement control measures to enhance HSE awareness. The key responsibilities of consultants in this regard can be summarized as follows:

1. Risk Assessment: Consultants are responsible for conducting thorough risk assessments within coal-fired power plants. They evaluate the potential hazards and assess the associated risks. By identifying these risks, consultants can recommend appropriate control measures to mitigate them effectively. Their expertise ensures a comprehensive evaluation of all potential hazards, including but not limited to electricity production, wastewater treatment, and battery manufacturing.

2. Hazard Identification: In addition to risk assessment, consultants are skilled in identifying various hazards present in coal-fired power plants. These hazards may include the degradation of organic waste, the use of personal protective equipment, and the generation of landfill gas. Through their expertise, consultants can pinpoint potential risks and provide insights into necessary safety measures. Their regular audit and analysis help identify areas of improvement in terms of occupational health and overall HSE practices.

3. Control Measure Implementation: Implementing appropriate control measures is crucial in maintaining a safe working environment. Consultants guide coal-fired power plants in the development and implementation of control measures. This involves ensuring the proper use of personal protective equipment, adhering to industry regulations, and establishing policies that prioritize the welfare of workers. Consultants oversee the formulation of safety policies and facilitate their effective implementation, making certain that the highest standards of HSE awareness are consistently met.

4. Continuous Improvement: Consultants emphasize the importance of continuous improvement in enhancing HSE awareness among workers in coal-fired power plants. They encourage organizations to foster a culture of safety by regularly reviewing and updating their safety programs. With a focus on the long-term sustainability of waste-to-energy implementation, consultants provide recommendations for improvement in key areas such as waste management practices, training programs, and the formulation of safety policies. By promoting continuous improvement, consultants ensure that HSE practices remain up-to-date and aligned with evolving industry standards.

5. Adherence to Relevant Legislation: Consultants are well-versed in the laws and regulations pertaining to occupational safety and health. They ensure the compliance of coal-fired power plants with regard to the relevant legislation. By guiding organizations in policy development, risk assessment, and control measure implementation, consultants enable them to meet legal obligations. Their expertise helps companies stay updated on the latest regulations and maintain a safe working environment for their employees.

Strategies for Enhancing HSE Awareness

To improve HSE (Health, Safety, and Environment) awareness among Malaysian workers in coal-fired power plants, various strategies and best practices can be implemented. These strategies aim to create a safe and healthy work environment, mitigate potential hazards, and promote the overall well-being of workers. The following key areas should be considered for enhancing HSE awareness:

1. Training Programs

Implementing comprehensive and regular training programs is essential to ensure all workers have the necessary knowledge and skills to identify and manage risks effectively. Training should cover topics such as hazard identification, emergency response procedures, proper use of personal protective equipment (PPE), and safe working practices specific to the coal-fired power plant industry.

2. Effective Safety Programs

Developing and implementing robust safety programs is crucial for improving HSE awareness. These programs should include regular safety inspections, incident reporting systems, and continuous monitoring to identify areas of improvement. Encouraging workers to actively participate in safety initiatives and providing incentives for good safety practices can help create a safety-conscious culture within the workplace.

3. Waste Management Practices

Proper management of waste generated in coal-fired power plants is essential for maintaining a safe working environment. Implementing appropriate control measures for handling hazardous materials, establishing waste disposal protocols, and promoting recycling and waste reduction initiatives can significantly contribute to HSE awareness.

4. Formulation of Safety Policies

Developing and enforcing comprehensive safety policies is critical for enhancing HSE awareness and compliance. These policies should address specific responsibilities, risk assessment procedures, and safety measures related to various aspects of work, including operational activities, maintenance protocols, and emergency response protocols. Regular review and revision of safety policies based on evolving industry regulations and best practices are important for maintaining effectiveness.

5. Continuous Improvement

Regular evaluation of HSE practices and performance is necessary to identify areas of improvement. Engaging in regular audits, conducting feedback sessions with workers, and analyzing incident reports can provide valuable insights for enhancing HSE awareness. Continuous improvement initiatives should focus on addressing identified gaps, implementing necessary corrective measures, and ensuring the long-term sustainability of HSE improvement efforts.

Challenges and Future Prospects

Ensuring high standards of Health, Safety, and Environment (HSE) awareness among Malaysian workers in coal-fired power plants poses several challenges. These challenges require proactive measures and a collective effort from stakeholders to create a safe and healthy work environment. Additionally, addressing these challenges presents an opportunity for the future improvement of HSE practices in the industry.

Challenges in Enhancing HSE Awareness

1. Cultural Mindset and Awareness

One of the key challenges is cultivating a strong safety culture and increasing awareness of HSE practices among workers. Often, the cultural mindset places more emphasis on productivity rather than safety, creating a barrier to effectively promoting HSE awareness. Overcoming this challenge requires continuous education and training programs that emphasize the importance of HSE practices and their impact on both personal well-being and organizational performance.

2. Hazard Identification and Risk Assessment

Identifying potential hazards and conducting thorough risk assessments are integral parts of improving HSE awareness. The complex nature of coal-fired power plants and the multitude of potential hazards make this process challenging. It requires the expertise of consultants who can assess the specific risks associated with the industry, such as exposure to harmful emissions, handling of hazardous materials, and the risk of accidents. Regular audits and the involvement of consultants in this process can contribute to a safer working environment.

3. Adequate Control Measures

Implementing appropriate control measures is essential for minimizing risks in coal-fired power plants. However, identifying and implementing the most effective control measures can be a challenge. It requires a comprehensive understanding of the potential hazards, available technologies, and industry regulations. Consultants play a crucial role in suggesting the best practices for control measure implementation and ensuring the necessary safety measures are in place to protect workers.

4. Addressing the Renewable Energy Transition

As the world transitions towards renewable energy sources, coal-fired power plants face the challenge of maintaining HSE standards while adapting to changing technologies and energy production methods. The industry must invest in research and development to explore cleaner and more sustainable options, such as Waste-to-Energy (WTE) technologies. Consultants can provide guidance on optimizing energy production methods, ensuring a balance between energy needs and environmental protection.

Future Prospects for HSE Improvement

While challenges persist, there are promising prospects for enhancing HSE awareness among Malaysian workers in coal-fired power plants. The following areas warrant attention for future improvement:

1. Collaboration and Industry Regulation

Collaboration among industry stakeholders, including power plant operators, consultants, and regulatory bodies, is crucial to driving HSE improvements. Continuous dialogue and knowledge sharing can lead to the formulation of comprehensive safety policies, implementation of best practices, and adherence to relevant legislation.

2. Technological Advancements

Advancements in technology offer opportunities for improving HSE practices. These include the use of automation to minimize human exposure to hazardous environments, the implementation of IoT (Internet of Things) devices for real-time monitoring of safety parameters, and the development of training programs utilizing virtual reality for immersive learning experiences. Embracing these advancements can greatly enhance HSE awareness among workers and facilitate safer operating conditions.

3. Continuous Improvement and Training

To ensure long-term sustainability of HSE improvement, a focus on continuous improvement is essential. Regular training programs should be designed to address emerging risks and promote a proactive approach towards health and safety. Engaging workers through interactive and tailored training sessions can reinforce the importance of HSE practices and foster a safety-conscious culture within the industry.

Conclusion

Consultants play a crucial role in enhancing HSE (Health, Safety, and Environment) awareness among Malaysian workers in coal-fired power plants. Throughout this article, we have highlighted their key responsibilities, strategies, and successes in improving safety practices.

Consultants act as catalysts for change by implementing control measures and conducting thorough risk assessments. They help organizations identify potential hazards and develop appropriate control measures for a safe working environment. Adherence to relevant legislation ensures the welfare of workers and the long-term sustainability of waste-to-energy (WTE) implementation.

Continuous improvement is essential, and consultants guide organizations in formulating effective safety programs, providing training programs, and establishing sound waste management practices. By involving consultants, companies can benefit from their expertise in policy development and the formulation of safety policies.

Moving forward, the challenges in HSE awareness enhancement must be addressed to ensure a safe and sustainable future. The industry must consider technological advancements and industry regulations to further improve occupational health and safety practices.