Introduction

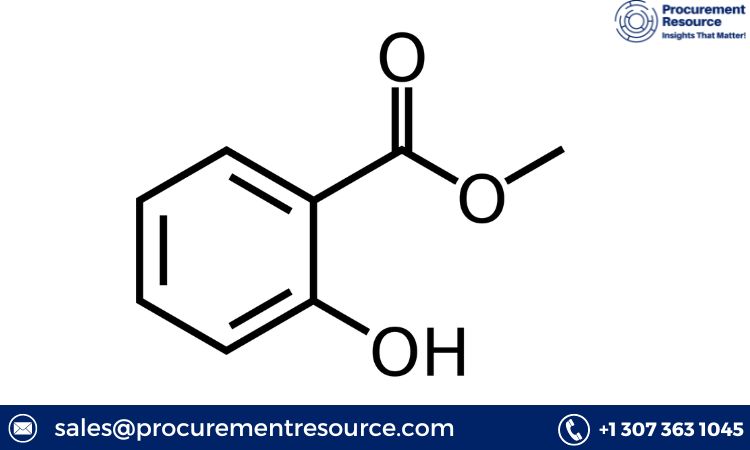

Methyl Salicylate, also known as wintergreen oil, is a versatile compound widely used in pharmaceuticals, cosmetics, and flavorings. Understanding the intricacies of the Methyl Salicylate production process and associated costs is crucial for stakeholders in the industry. In this press release, we explore the Methyl Salicylate Production Process with a comprehensive cost analysis, aiming to provide valuable insights for businesses.

Request Free Sample – https://www.procurementresource.com/production-cost-report-store/methyl-salicylate/request-sample

Procurement Resource Assessment Methyl Salicylate Production Process

The Methyl Salicylate production process begins with a meticulous procurement resource assessment. This involves evaluating raw material sources, production technologies, and regulatory considerations. By conducting a thorough assessment, producers can optimize resource procurement, enhance production efficiency, and mitigate risks.

Product Chloride

Chloride serves as a catalyst in the Methyl Salicylate production process, facilitating the conversion of salicylic acid and methanol into Methyl Salicylate. Chloride-based catalysts play a crucial role in accelerating chemical reactions and improving process efficiency. Ensuring high-quality chloride products is essential for maintaining process integrity and product quality.

Market Drivers

Several factors act as drivers shaping the Methyl Salicylate market landscape. These include fluctuations in raw material prices, changes in consumer preferences, regulatory policies, and advancements in production technologies. Understanding these market drivers is essential for forecasting market trends, identifying growth opportunities, and mitigating risks.

Raw Materials Requirements

The raw materials required for Methyl Salicylate production include salicylic acid, methanol, and catalysts. Salicylic acid is typically derived from natural sources such as wintergreen oil or synthesized from phenol. Methanol serves as a solvent and reactant in the production process, while chloride-based catalysts facilitate the reaction. Additionally, energy sources such as steam and electricity are essential for various stages of the production process.

Costs and Key Process Information

Methyl Salicylate production costs are influenced by factors such as raw material prices, energy consumption, labor costs, equipment maintenance, and regulatory compliance. Key process information, including production capacity, process efficiency, and plant location, also impacts production costs. Analyzing these factors allows producers to optimize production processes, enhance cost-effectiveness, and maintain competitiveness in the market.

Looking for an Exhaustive and Personalized Report

For businesses seeking an exhaustive and personalized Methyl Salicylate production process cost report tailored to their specific needs and objectives, our team offers comprehensive analysis and insights. Our reports encompass detailed cost breakdowns, market analysis, procurement strategies, and future outlooks, providing valuable information to substantiate business decisions.

In conclusion, understanding the Methyl Salicylate production process and associated costs is essential for stakeholders in the industry. By conducting thorough assessments, analyzing market drivers, and optimizing production processes, businesses can enhance efficiency, reduce costs, and capitalize on market opportunities.

For businesses seeking a detailed Methyl Salicylate production process cost report to substantiate their operations and strategic initiatives, our team is dedicated to providing personalized and comprehensive analysis. Contact us today for more information.

About Us: